Navigating the World of Unsold CNC Machines: A Comprehensive Guide

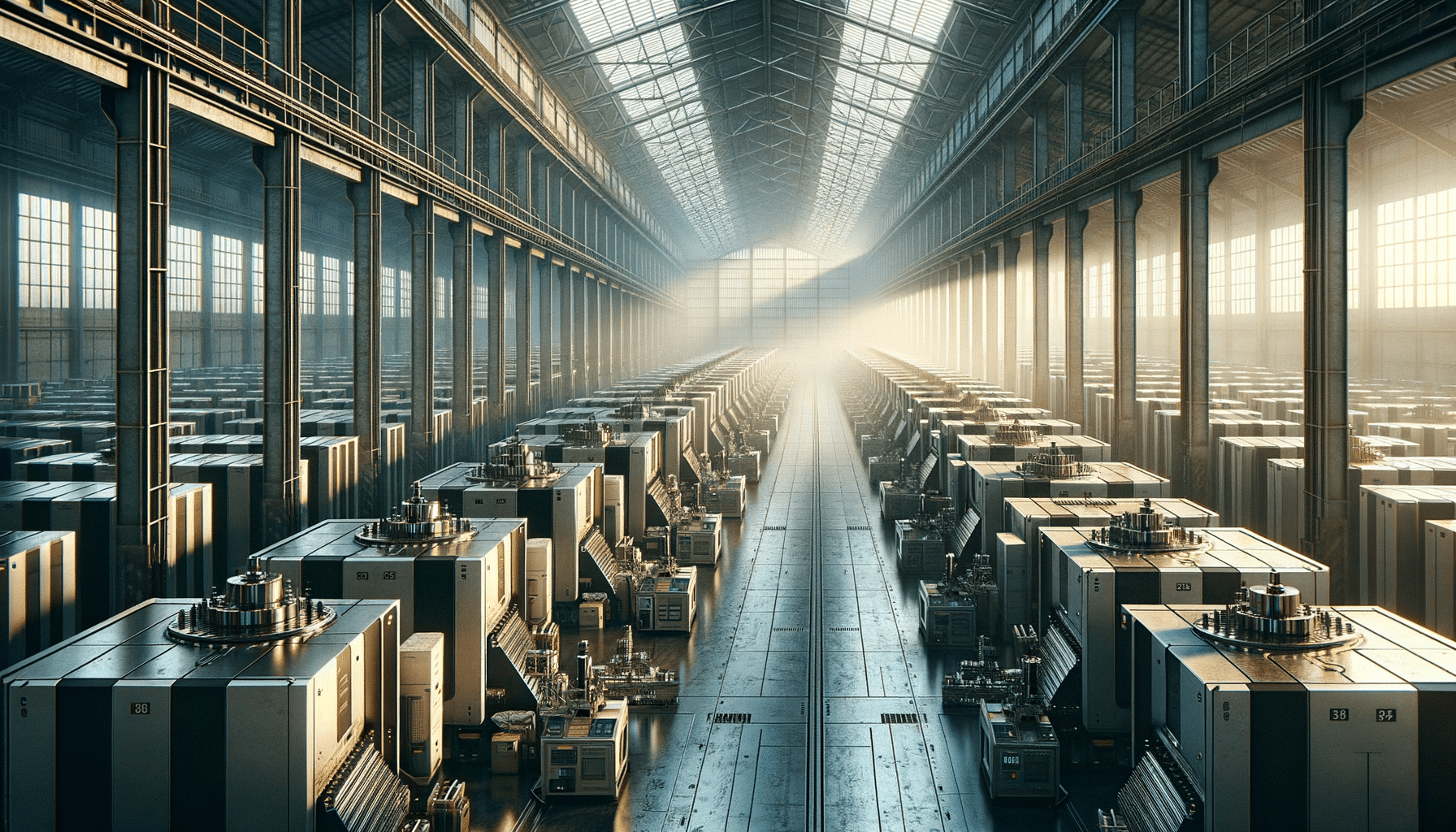

Introduction to Unsold CNC Machines

In the ever-evolving world of manufacturing, Computer Numerical Control (CNC) machines play a pivotal role in precision engineering and mass production. However, despite their importance, a significant number of these machines remain unsold. Understanding the dynamics behind unsold CNC machines can offer insights into market trends, pricing strategies, and potential opportunities for buyers and sellers alike. This article delves into the reasons behind unsold CNC machines, exploring the implications for the industry and potential buyers.

Reasons Behind Unsold CNC Machines

The phenomenon of unsold CNC machines can be attributed to various factors. Primarily, technological advancements lead to frequent updates and newer models, which can render older versions less appealing. As manufacturers strive for efficiency and innovation, older models may fail to meet the latest industry standards, leaving them unsold in warehouses.

Additionally, economic fluctuations play a significant role. During economic downturns, companies might delay or reduce their investments in new machinery, leading to a surplus of unsold units. Moreover, the high initial cost of CNC machines can deter small to medium enterprises from making such significant investments, contributing to the unsold inventory.

Another factor is the rapid pace of technological obsolescence. As CNC technology evolves, older models may quickly become outdated, making it challenging for sellers to find buyers interested in purchasing machines that may not support newer software or capabilities.

Finally, market saturation in certain regions can result in an oversupply of CNC machines. When the local demand is met, additional units remain unsold, waiting for potential buyers from other regions or industries.

Implications for the Manufacturing Industry

The presence of unsold CNC machines has several implications for the manufacturing industry. For manufacturers, holding onto unsold inventory can tie up capital and resources, impacting cash flow and profitability. This situation often forces them to offer significant discounts or promotions to clear out excess stock.

For buyers, unsold CNC machines present an opportunity to acquire high-quality equipment at reduced prices. Businesses looking to expand their production capabilities without incurring the full cost of brand-new machines can benefit significantly from purchasing unsold units.

However, buyers should be cautious and conduct thorough evaluations of the machines’ condition and compatibility with their existing systems. The potential cost savings must be weighed against any additional expenses for upgrades or maintenance required to integrate older machines into current production lines.

Moreover, the trend of unsold machines can spur innovation as manufacturers strive to create more versatile and adaptable machines that can cater to a broader range of industries and applications, reducing the risk of obsolescence.

Strategies for Selling Unsold CNC Machines

Manufacturers and distributors can adopt several strategies to address the challenge of unsold CNC machines. One effective approach is to enhance their marketing efforts, targeting niche markets or industries that may have a demand for specific types of machines. Tailored marketing campaigns can help in reaching potential buyers who may not be aware of the available inventory.

Offering flexible financing options or leasing plans can also attract buyers who are hesitant to commit to a significant upfront investment. These options can make CNC machines more accessible to smaller businesses or startups looking to enhance their production capabilities.

Furthermore, collaborating with online platforms and industry-specific marketplaces can increase visibility and reach a broader audience. By listing unsold CNC machines on these platforms, sellers can connect with potential buyers globally, expanding their market beyond local constraints.

Finally, investing in refurbishing and upgrading unsold machines can make them more appealing to buyers. By ensuring that the machines are in optimal working condition and compatible with the latest technologies, sellers can enhance their value proposition and increase sales prospects.

Conclusion: Opportunities in Unsold CNC Machines

Unsold CNC machines represent both challenges and opportunities within the manufacturing industry. While they can be a burden for manufacturers, they also offer a chance for buyers to acquire essential equipment at reduced costs. By understanding the factors contributing to unsold inventory and implementing strategic solutions, stakeholders can turn this challenge into a beneficial opportunity.

For potential buyers, the key lies in conducting thorough research and evaluations to ensure that the machines meet their production needs and standards. For sellers, embracing innovative marketing strategies and flexible sales options can help in reducing unsold inventory and enhancing business growth.

Ultimately, the landscape of unsold CNC machines highlights the dynamic nature of the manufacturing industry, where adaptability and strategic foresight can lead to success.